Capacitor Foil

Electrostatic capacitance (a representation of the performance of electrolytic capacitors) is directly proportional to the surface area of the capacitor electrode foil, which requires a high bending strength. In order to increase the surface area by tens upon hundreds of times, aluminum foil for capacitors is treated electrochemically. However, while the greater surface area results in improved capacitance, bending strength tends to decrease.

UACJ and UACJ Foil collaborate to solve this dilemma. By utilizing highly pure aluminum ore slabs tempered with trace chemical components, as well as specialized manufacturing and quality control systems, we can produce electrolytic capacitor foil with both improved capacitance and high bending strength.

Characteristics

The surface ratio of aluminum capacitor foil increases yearly while customer demands grow more sophisticated.

UACJ Foil employs mechanical property/performance qualification and etching test equipment to ensure that products meet expected quality.

At the UACJ Technical Research and Development Center, we also analyze items such as the effect of trace components and precipitates on pit generation, utilizing product performance tests to continually improve processing technologies.

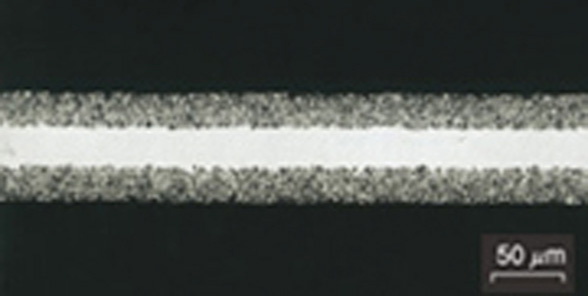

Cross-section of high-voltage, aluminum electrolytic capacitor electrode foil

Cross-section of low-voltage, aluminum electrolytic capacitor electrode foil

Applications

- Office equipment, audio-visual equipment (computers, digital televisions, DVD players, audio equipment)

- Information devices (mobile phone battery components, information infrastructure)

- Automotives (electrical equipment, electric vehicles, hybrid vehicles)

- Power-saving equipment (inverter-based home appliances)