Copper Foil

All of UACJ Foil’s copper foil is order made. We tailor our products to fit customer needs, including materials, measurements and material properties. Our reliable high-quality, high-grade copper foil is used in a variety of products such as cutting-edge electronics, high-end consumer appliances and luxury foods.

We constantly strive to create next-generation applications for copper foil using innovative ideas and solid R&D.

Characteristics

UACJ Foil offers world-quality, wide-sheet copper foil for FPC, batteries, electrical lines and other applications. Find out more about the advantages of UACJ Foil’s rolled copper foil.

| Tough Pitch Copper, Oxygen-free Copper | |

|---|---|

| Refining | Softness, hardness |

| Measurements | Thickness: ultra-thin (4 μm and up)/Width: wide-sheet (up to 650 mm) |

Applications

- Electromagnetic wave shielding

- Printed circuit boards

- Lithium-ion battery

- Antibacterial copper foil application, etc.

Low-roughness Rolled Copper Foil

Using sophisticated rolling technologies accumulated over many years, UACJ Foil has developed rolled copper foil with minimal surface roughness. We can realize a surface roughness (surface roughness meter) of Rz 0.4 μm, allowing manufacture of fine pattern circuits.

Characteristics

- Available in surface roughness (surface roughness meter) as fine as Rz 0.4 μm.

- Suited for fine pattern circuits.

- Supports high frequencies (GHz), and suited for circuit patterns resistant to skin effect.

Specifications

| Materials | Tough pitch copper |

|---|---|

| Thickness | 8-35 μm |

| Width | 250-650 mm |

| Surface processing | It will be provided as a single foil.We do not accept surface treatment. |

Applications

- Fine pattern/high frequency printed wiring boards, etc.

Characteristics

Mechanical/electrical characteristics (12 μm thickness)

| Item | Representative Value |

|---|---|

| Tensile strength normal condition (MPa) | 450 |

| Stretchability normal condition (%) | 1.4 |

| Electrical conductivity | 101 |

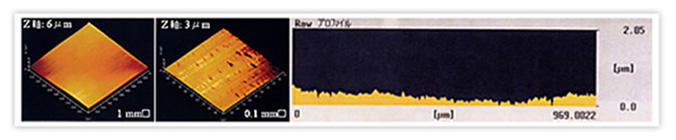

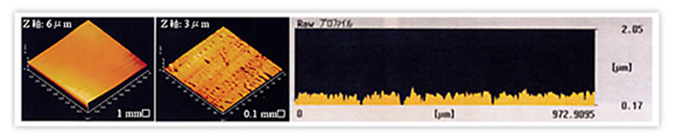

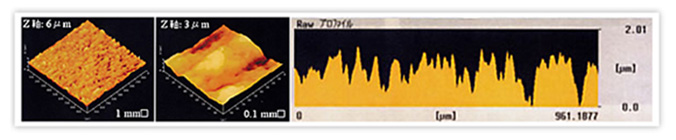

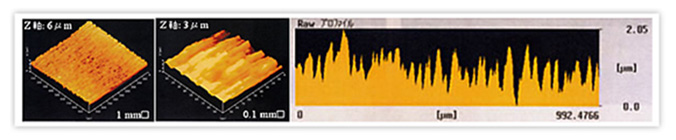

Surface roughness

| Sample | SRM (Surface Roughness Meter) | AFM | ||

|---|---|---|---|---|

| Rz | Ra | Rz | Ra | |

| ES foil | 0.4 | 0.05 | 0.24 | 0.13 |

| Previous UACJ Foil rolled copper foil | 0.7 | 0.09 | 0.4 | 0.31 |

| Electrolytic copper foil M surface | 1.5 | 0.27 | 1.2 | 0.26 |

| Electrolytic copper foil S surface | 1.8 | 0.33 | 1.3 | 0.27 |

Surface photograph (SEM image)

Surface shape (AFM image)