Bare Foil

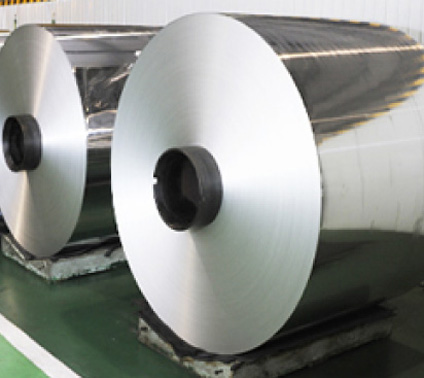

Aluminum foil is created by rolling highly pure and thinly rolled base foil into an even thinner gauge (200 μm or less).

UACJ Foil manufactures aluminum foil from high-quality, bare foil cast that we roll ourselves. Foil is optimized for specific applications by tailoring thickness and composition.

Specifications

| Alloy Number | Thickness | Major Applications | Characteristics |

|---|---|---|---|

| 1N30 | 6 μm-200 μm | Food, pharmaceuticals, etc. | 99.30% (or greater) pure aluminum |

| 1085 | 12 μm-200 μm | Electrolytic capacitors, etc. | 99.85% (or greater) pure aluminum |

| 1N90 | Electrolytic capacitors, etc. | 99.90% (or greater) pure aluminum | |

| 1N99 | Electrolytic capacitors, etc. | 99.99% (or greater) pure aluminum | |

| 3003 | 12 μm-200 μm | Ornamental panels, etc. | Highly strong and durable |

| 3004 | 30 μm-200 μm | Ornamental panels, etc. | Highly strong and durable |

| 8079 | Food, pharmaceuticals, etc. | Minute and uniform crystalline structure | |

| 8021 | 6 μm-200 μm | Food, pharmaceuticals, etc. | High-performance aluminum foil |

Alloy 8021 for High-performance Aluminum Foil

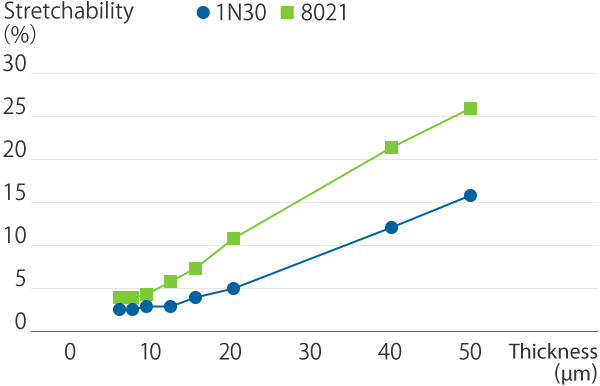

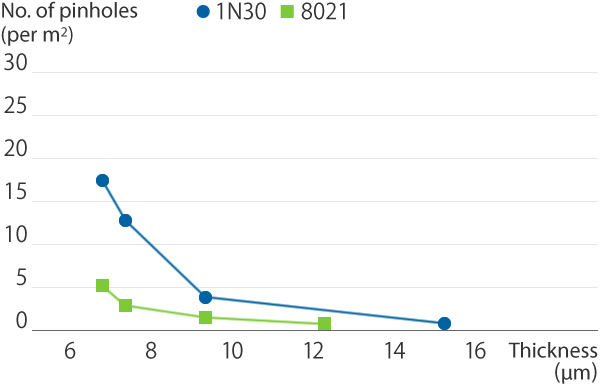

High-performance foil 8021 is an alloy created from pure, aluminum base foil tempered with additional elements. Compared to the IN30 variety generally used for foil, it is extremely workable and has high tensile strength and stretchability. It also has excellent design properties, with minimal pinholes and uniformly smooth matte surfaces.

Characteristics

1. Reduced costs

Minimal pinholes (a 70% reduction compared to UACJ Foil 7μ) ensures better performance for applications such as pharmaceutical packaging, electronics packaging, retort packaging and LL containers, all of which require barrier performance. This better performance helps reduce costs.

2. Improved quality of molded products

Exceptional stretchability (a 70% increase compared to UACJ Foil 7μ) can improve the quality of molded products that require difficult bending, such as gusset bags, standing pouches and lamination tubes.

3. Improved lamination productivity

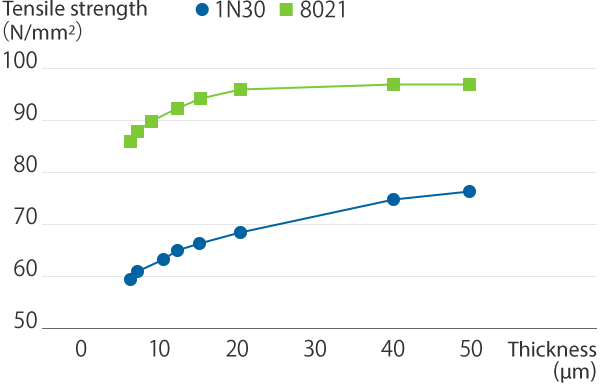

High tensile strength (a 40% increase compared to UACJ Foil 7μ) greatly improves productivity by helping prevent tearing during lamination.

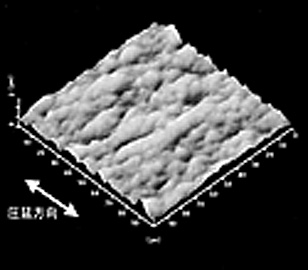

4. Improved product appearance thanks to uniform and smooth surfaces

The smoother and more uniform matte surface helps improve the appearance of products, making the foil excellent for labels and other external packaging.

Specifications

Chemical composition (mass%)

| Product Name | JIS | Si | Fe | Cu | Mn | Mg | Zn | Other | Al |

|---|---|---|---|---|---|---|---|---|---|

| 8021 | 8021 | ≦0.15 | 1.2≦ ≦1.7 |

≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | Remainder |

| Previous material | 1N30 | Si+Fe≦0.7 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | |||

Available sizes, luster

| Thickness | 7-60 μm | 12-60 μm | 60-150 μm |

|---|---|---|---|

| Luster | One-sided | One-sided/Two-sided | Two-sided |

| Width | 50-1200 mm | ||

Properties

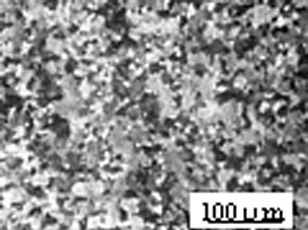

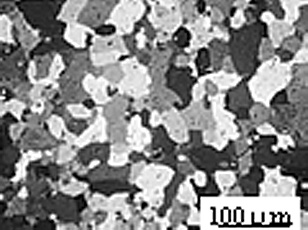

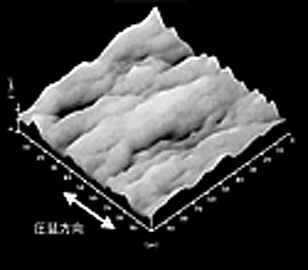

1. The fine crystalline structure reduces surface roughness, allowing for sharper printing of characters.

Crystalline Structure

Surface roughness

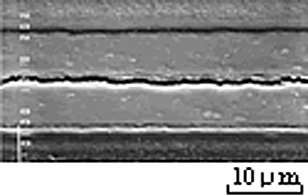

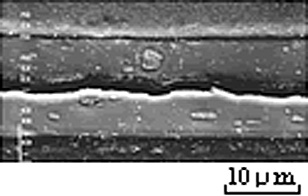

Crystal Grain Size

| Product Name | Crystal Grain Size (μm) |

|---|---|

| 8021 | 5-10 |

| Previous material | 30-100 |

2. Fine crystals and precipitates reduce waviness on the processed surface and pinholes.

Analysis of Aluminum Cross-section Crystals/Precipitates

Mechanical Properties(softness)

Pinholes(compared to previous UACJ materials)

The crystal grains of high-performance foil 8021 are small, with minute and uniform inter-metallic compounds. This results in a finer matte surface and fewer pinholes. The difference is particularly noticeable for ultra-thin foil.

The value is a representative value and does not guarantee the numerical value.

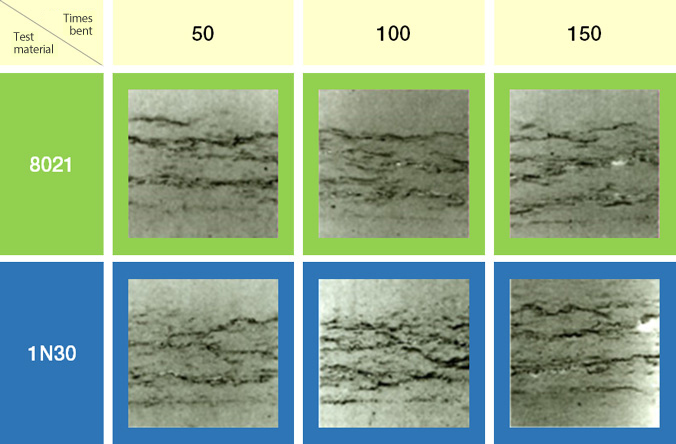

3. Excellent bendability and durability.

In salt spray tests and accelerated tests in hot and humid environments, high-performance aluminum foil demonstrated durability equal to or better than previous materials.

Bending

Applications

- Medical packaging, household goods

- Pharmaceutical packaging

- Battery tab materials

- Other